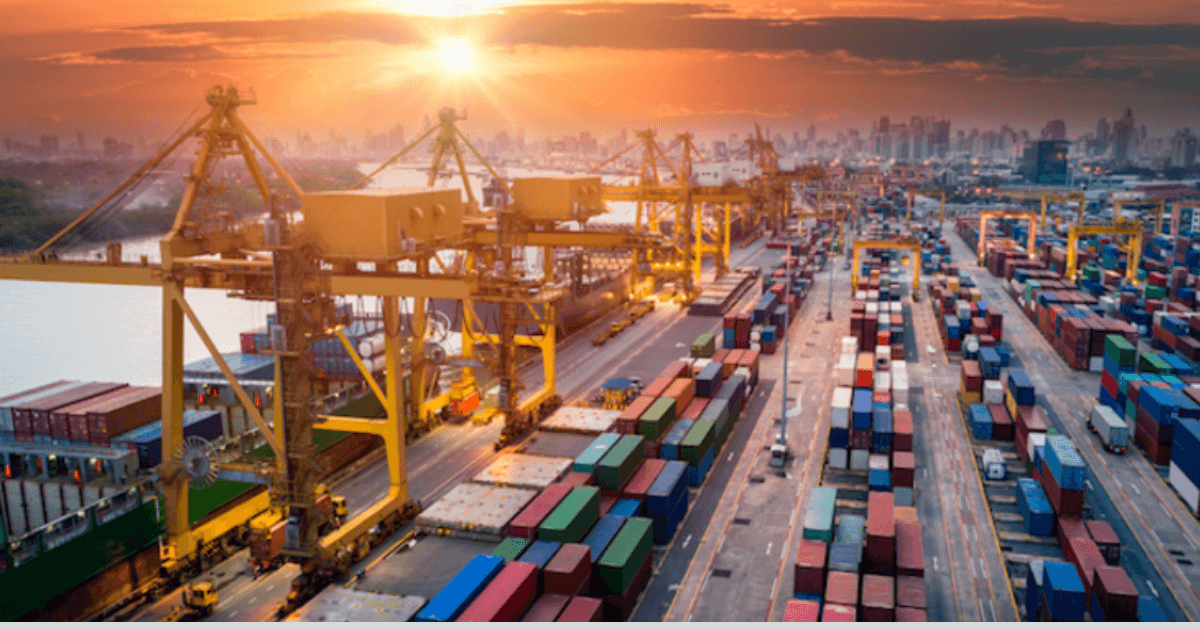

Amid Global Supply Chain Slowdown, Nearshoring Picks Up Speed

Companies have been gradually moving production closer to intended markets for years, but nearshoring is now picking up speed amid global supply chain slowdowns.

In many cases, companies’ nearshoring plans were well underway before the pandemic but have since been accelerated. In fact, many teams—especially in the toy industry—started shifting manufacturing from China to Vietnam and Malaysia several years ago in response to the U.S. Trade Representative slapping 25% tariffs on imported goods. But, after more than a year of delays along every link in the supply chain, nearshoring is gaining favor across product categories.

Mattel, for one, announced it would spend $50 million to expand production at a plant in the northern Mexican state of Nuevo Leon. The facility, which produces items including Barbie, Hot Wheels, and Mega Bloks, will become Mattel’s largest plant, overtaking manufacturing hubs in China, Malaysia, and Vietnam. The toymaker closed three plants in China in 2019 and a plant in Montreal in 2021 as part of CEO Ynon Kreiz’s plan to overhaul the company’s supply chain.

In Europe, 88% of respondents to an Ernst & Young survey said they were considering nearshoring, with 61% seeking to reduce their reliance on China. And 172 of 260 executives with manufacturing in China expressed interest in Mexico to supply the U.S. market, according Border Now.

“The [logistics issues] have highlighted how reliant the Australian market is on China—especially anything that has a lot of components and it’s refocused the consumer on where the goods they purchase come from,” said Asembl Brands’ managing director Justin Watson, whose firm represents brands including Guinness, Men’s Health, and Bailey’s.

Yet not all companies are so quick to move production outside of China. Many licensing executives point to the region’s lower costs and production efficiency, with many plants located near component and materials sources.

Basic Fun, which has, among others, licenses for Care Bears plush as well as Pac-Man and Tetris mini-arcade games, has contracted production in Burnham, Maine (Lincoln Logs) and Hatfield, Pennsylvania (K’Nex) due to the “price being right” for wood and plastics as well as expertise associated with both plants, CEO Jay Foreman said. Basic Fun remains committed to manufacturing in China, however.

“It is not that easy to get financing to build or expand a plant [in the U.S.] even if you can find the labor and management to run it,” Foreman said. “I hope the logistics issues are only for a year or two but we need ports expanded, more capacity for shipping by sea, rail, and truck, and more labor on our end in order to move” production back to the U.S.